2d Screw Shell Extruder Food Production Line

Brand :DELON

Product origin :SHANDONG JINAN

Delivery time :15 WORKING DAYS

Supply capacity :15 SETS

The production line uses corn powder,wheat powder and rice powder as main raw material.

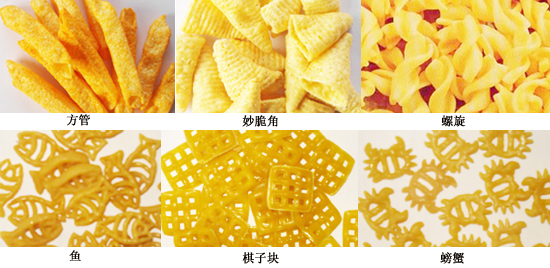

By extruding,roller pressing or punching to make a variety of shapes,such as triangle,round and

cartoon etc.After frying or baking and flavroing,it can mmake various flavors snacks.

Buy Screw Extruder Machine, Brands Extruder Machine, Snack Food Extruder Suppliers, Food Extruder Factory

2d Screw Shell Extruder Food Production Line

Brief introduction of twice extrusion 3d 2d tube/burgles snack food processing machine This line adopts wheat flour,corn starch,potato starch ,potato whole flour as raw material Through screw extruding it shapes up various shapes 2D,3D billets ,then through drying,frying,flavoring , delicate taste crisp ,smooth surface ,shape lifelike puffed leisure food comes true . Our unit screw combination technology and precise control for production process that makes you wider raw materials selection ,higher product quality and various variety.

2d Screw Shell Extruder Food Production Line

1. Raw Materials: Main corn Powder and Other Cereals Powder etc

2. Products: All kinds of snacks with different shapes and types.

3. Capacity: 80-120 KG/H,100-150KG/H ,250-350 KG/H

4. Flow Chart: Mixing —Extruding —Pattern pressing—Shaping — Baking —Frying —Flavoring —Cooling

5. Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ,

also can make it according to customers' local voltage of different countries

6. Machines Materials: All the machines are made by food grade stainless steel.

Note: This line can not only produce 3D&2D various shapes snacks food which can be storage ,sold and conveyed easily after baking.

But also can directly produce puffed snacks food by our twin screw extruder.

Brief introduction of single machines of twice extrusion fried 3d 2d snacks pellet production line:

1. Flour mixer: to mix various flour evenly.

2. Screw conveyor: to convey raw material to the extruder

3. Twin screw extruder: to puff and cook raw material into different shapes .

4. Pattern presser: to press various pattern on the sancsk food .

5. Compound shaping machine : to compund shape various sapes ,such as ,round ,triangle,diamond,racket,flower ,animal shapes etc.

6. Punching machine : to punch food into single-layer round chips.

7. Square tube cutting machine: to cutt into tube shape.

8. Belt conveyor: to convey food to next machine.

9. Reciprocating drying machine: to dry twice -extrusion snaks food in order to fry or storage.

10. Vibrating cooler : to spread food avoid stick.

11. Frying machine: to fry snacsk pellet to ready-eat snacks food. (there are also other various kinds fryer can be choose)

12. De-oilling machine: to filt and de-oil the oil of fried snacks food.

13. Flavoring machine: to spray seasons on the snack food to get various tasty food.

Compound machine ( two functions : pattern pressing and shaping )

Our Service & Turnkey Solution

2d Screw Shell Extruder Food Production Line

a.) Consultation service before, during,and after sales;

b.) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) New production techniques and formulas

g.) Provide 1 year complete warranty and life-time maintenance service.