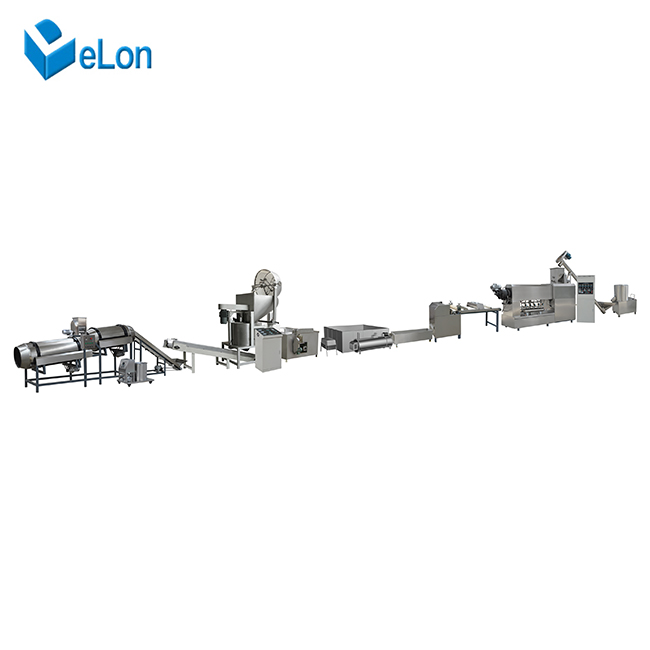

3D Pellet Snacks Production Line

Brand :DELON

Product origin :SHANDONG JINAN

Delivery time :15 WORKING DAYS

Supply capacity :23 SETS

Automatic Fried Extrusion Food 3D Pellet Snacks Process Line uses potato starch, potato flour, corn starch, corn powder, wheat flour, cassava starch etc as main materials, by the process of mixing, extruding, shaping and drying to produce dried double layer 3D pellets.

After changing cutting roller on Shaping machine, this line can produce many innovative shapes, like Triangle, Oval, Racket, Hexagonal (Sixer), Rectangle, Christmas tree, Animal, Zig Zag, Heart etc. After frying, the pellet will expand to several times, spraying some seasoning powder will make them much crispy and savory.

This line is characterized by unique technique, rational configuration, high automation and stable performance.

Buy 3D Pellet Snacks Production Line, Custom Snacks Production Machines, Snack Food Machine Price

1. Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2. Adopting speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3. Gearbox with automatic lubrication function, extending gear life.

4. Increased radiator on driving part for forced cooling effect, ensuring extruder operates safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

VI. We Provide Satisfied Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

1. Mixer:mix raw material equally according to the recipe

2. Spiral Conveyor: take the raw material to the extruder

3. Extruder : cook and extrude the raw material with certain pressure and temperature to make different shapes of snacks

4. Cooling vibrator :cool down and vibrate the snacks to avoid them stick together

5. Punching shaper : this machine is used to make round chips

6. Pulling&cutting machine : to make tubes shape

7. Low temp dryer: dry the pellets to take away the surface moisture and store the pellets for a certain time

8. oven(circulating): dry the snack pellets for more than 2 hours with circulating conveyor

Processing line | Installed power | power consumption | Dimension | output |

DL100 | 64 kw | 48 kw | 25000*2600*2400 | 80~120kg/h |

DL-II | 72 kw | 54 kw | 28000*2600*2400 | 100~150 kg/h |

DL-II | 132 kw | 99 kw | 44200*5600*3000 | 200-250 kg/h |

DL-II | 241 kw | 181 kw | 40000*6000*3500 | 400~500kg/h |

Application | Processing line |

2D pellets made from potato starch | DL100 processing line |

2D&3D pellets made from corn flour ,wheat flour and starch | DL52-II processing line DL75-II processing line DL75-VIII processing line DL90-II processing line |

Swiss Technology,made in China;

PLC touch screen for Centralized ,accurate,convenient control

Fully automatic control system for heating and circulated cooling accurately

Direct transmission of motor and distribution box reduces energy loss.

Imported bearing group with higher bearing capacity

Equip with water injecting device on barrel to meet require of various raw material and quality.

High-speed tool steel with hardness HRC≥62 to ensure a longer service life.

Modular combination of screws at will to meet require of different raw material.

Suspension type rotary cutter with bearing adjusting device to ensure quick,safe and accurate

All barrels inlaid alloy sleeve, easy to replace and extend the life span of screw. All barrels inlaid cooling water through, spread around alloy sleeve, and can accurate constant temperature required

All screw sleeves is kneading, ensure that not accumulate material. The screw is installed by blocks, and can be replaced optionally ratio to achieve requirements for product. Screw sleeve is installed by spline, and it is convenient and efficient. Quality of screw sleeve according to different prices is divided into: Cr12MoV, 38CrMoAl38, W6Mo5Cr4V2.

Applied to make all kinds of extrusion products such as corn flakes , cereal snacks ,puff snacks ,wheaten snacks , 2d /3d snack pellets , pet food ,fish feed ,soya protein ,nutritiobal powder ,modified starch and so on .

Machine material details

Machine shield : 201 ss / 304 ss as required

Parts contact with food : 201 ss / 304 ss as required

Screw / barrel and cutter of the extruder : special alloy to bear high temp and pressure

Main parts : as follows