Fried Food Production Line

Brand :DELON

Product origin :SHANDONG Jinan

Delivery time :15 working days

Supply capacity :24 SETS

The Fried wheat flour based snack process line is for processing dough with wheat flour, and then shaping and cutting the skin into forming products. After being pressed by serious stainless rollers, they can be separately cut into pillow or stick shapes and expanded by frying. After that, they can be flavor-mixed and dried till they become appetizing and snack foodstuff. This line is reasonably designed and conveniently operated.

Fried Food Production Line

I. Fried Food Production Line Product Application

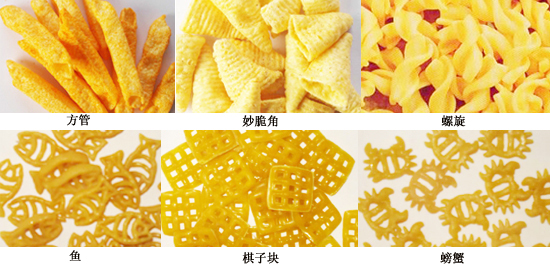

Fry snacks pellet fried snack is produced by single-screw extruder through extruding cooking; the pellet can be different shapes like shell, spiral, square tube, circle tube, and so on. After drying, the pellet needs frying to get expanded.

3D&2D Pasta Snacks Pellet Food Making Machine uses potato starch, potato flour, corn starch, corn powder, wheat flour, cassava starch etc as main materials, by the process of mixing, extruding, shaping and drying to produce dried double layer 3D pellets.

After changing cutting roller on Shaping machine, this line can produce many innovative shapes, like Triangle, Oval, Racket, Hexagonal (Sixer), Rectangle, Christmas tree, Animal, Zig Zag, Heart etc. After frying, the pellet will expand to several times, spraying some seasoning powder will make them much crispy and savory.

Fried Food Production Line This line is characterized by unique technique, rational configuration, high automation and stable performance.

Raw mareials:

Adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

II. Fried Food Production Line Flow chart:

Mixing system---Extrusion system----Cutting system---Drying system----frying machine-----flaviong machine --Packing system.

| Model | Installed power | Real power | Output | Dimension(mm) |

| DL-3000-100 Series | 89.6 kw | 60kw | 80-120 kg/h | 20000X3000X2500 |

| DL-3000-120 | 99.6KW | 70KW | 150-200kg/h | 22000×35000×26000 |

| DL-3000-120A | 110 KW | 80KW | 300-400KG/H | 25000×35000×26000 |

| DL-450 | 100KW | 90KW | 500-1000kg/h | 42000×45000×36000 |

III. Fried Food Production Line Main Features

1> Help client design the factory and offering professional advice, free engineering drawing for the factory layout.

2> Inspect the machine before leaving the factory.

3> Oversea install and debug the equipment.

4> Train the first-line operator.

5> Fry snacks pellet fried snack Provide the basic formula

1). Output: 80-120Kg/h

2). Fry snacks pellet fried snack Square for work shop: 100 ㎡and height 3.0 m

3). Real Power Consumption: 60 kW

4). Voltage / Frequency: 380V / 50Hz (can be changed to your country voltage)

5). Dimension (m): 20.0 x 5.0 x 2.4 m

6). Warranty: At least 1 year from the date of completion of the commissioning.

7). Installation/Operation/ Service/ Maintenance Manual: Provided In English.

V. We will provide on-site service after 1 year. The customer will be asked to provide room, board,round-trip transportation, and a nominal USD80 daily subsidy per person.

Pre-shipment Inspection Includes

a). Supplier should trial run whole line at supplier’s factory before shipment;

b). Supplier has to run the machine at least 1hour for each product;

c). All raw materials for that trial run to be arranged by supplier at their cost.

Each Client Can Enjoy The Following 7 Services

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

Installation Supervision And Commissioning

Including salaries based on 40 hours per week as well as accident-and health insurance for :

1 Chief Installation Engineer for the duration of 4 days in total.

1 Process Engineer for the duration of 2 days in total,

1 Electrical commissioning-Engineer for the duration of 1day in total

VI. Period of installation:

The total length of the installation time depends on number and qualification of the available local stuff.

A possible delay of the installation period will be additionally invoiced.

Remark: We will provide on-site service after 1 year. The customer will be asked to provide room, board, round-trip transportation, and a nominal 80