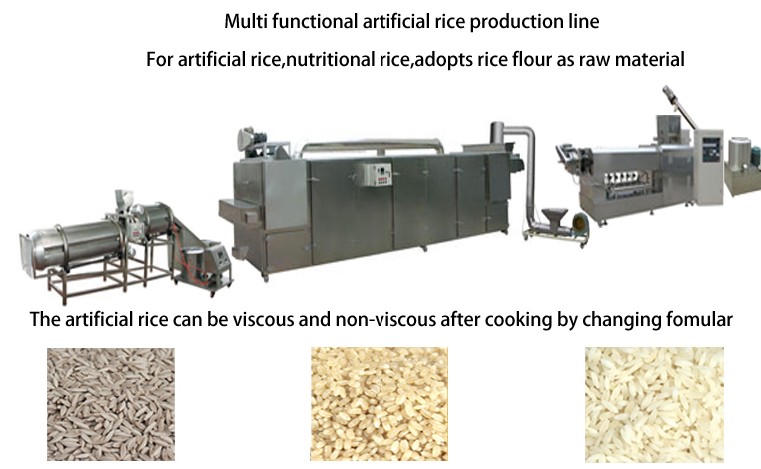

Artificial rice production equipment

Brand :DELON

Product origin :JINAN CHIAN

Delivery time :25 WAORKING DAYS

Supply capacity :156 SETS

Rice and it's by-products can be produced into highly nutritional foods by adding additional nutrient components after extrusion cooking. Further, for this process, the broken rice and rice bran can be reused. Process for making artificial rice grains,comprises a mixture of rice flour,water and oil in the extruder, forming into rice-grain shape,drying and cooling in low temperature.The technology makes it feasible to avoid the loss of nutrition.

Artificial rice production equipment

I. Artificial rice production equipment description

The rice processing machine is order to improve broken rice's value,mill the broken rice into rice powder, and then we make it into nice outlook,brightly, realistic rice

This process line is studied in concern with the loss of nutritional elements in the rice which is made by the traditional rice processing. Rice and it's by-products can be produced into highly nutritional foods by adding additional nutrient components after extrusion cooking. Further, for this process, the broken rice and rice bran can be reused. Process for making artificial rice grains,comprises a mixture of rice flour,water and oil in the extruder, forming into rice-grain shape,drying and cooling in low temperature.The technology makes it feasible to avoid the loss of nutrition.

II. Artificial rice production equipment feature

1. Raw material: Rice, millet, black riceand all kinds of corns and cereals .

2.Capacity of the Artificial rice production equipment : 120kg/h to 550kg/h .

3. Artificial rice production equipment materials: stainless steel and mild steel .

4. The biggest advantage of the Artificial rice production equipment :

The screw length is up to 1400mm, increasing compression and melting length than traditional 1000mm screw.

5. Artificial rice production equipment ---Flow chart:

Mixer--Screw conveyor-- Twin screw extruder-- conveyor--Mutilayer oven

We Provide Satisfied Service & Turnkey Solution ( rice processing machine )

III Artificial rice production equipment Technical Parameter

Model | Installed power | Real power | Output | Dimension |

DL65-III | 70kw | 40kw | 80-100kg/h | 20000x1200x1800mm |

DL70 | 86kw | 55kw | 100-120kg/h | 25000x1500x1800mm |

DL85 | 200KW | 150KW | 400-500KG/H | 30000X3500X1800MM |

IV Artificial rice production equipment Pre-sale service

1.Related machines’s technical parameter will be supplied to customer.

2.According to customer’s factory size, factory layout can be provided in advance.3. According to customer’s material cost, general formulation can be prepared well.

4.Special machine can be supplied as customer’s request.

5.Professional Advice about Market, machines, processing , materials, packing can be supplied

6. Suggesting professional ship agent or helping book ship as customer request.

V Artificial rice production equipment After sale service:

1.Allocation chart as the buyer’s request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer’s factory.

VI Artificial rice production equipment TECHNICAL PARAMETERS & RELEVANT SERVICES

1. Output: 50-100Kg/hr.

2. Artificial rice production equipment Square for work shop: 110 m2 and 3.0m high

3. Installed Capacity: 89.05kw Power consumption: 65.05kw

4. Voltage / Frequency: 380V / 50Hz

5. Dimension (m): 20.0 x1.5x 2.5 m

6. Workers Required: 1-2Workers

7. Warranty: At least 1 year from the date of completion of the commissioning.

8. Installation/Operation/ Service/ Maintenance Manual: Provided In English

VIIPRE-SHIPMENT INSPECTION INCLUDES

a). Supplier should trial run whole line at supplier’s factory before shipment;

b). Supplier has to run the machine at least 1hour for each product;

c). All raw materials for that trial run to be arranged by supplier at their cost.

VIII EACH CLIENT CAN ENJOY THE FOLLOWING 7 SERVICES

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

IX INSTALLATION SUPERVISION AND COMMISSIONING

Including salaries based on 40 hours per week as well as accident-and health insurance for :

1 Chief Installation Engineer for the duration of 1 week in total.

1 Process Engineer for the duration of 2 days in total,

1 Electrical commissioning-Engineer for the duration of 1day in total

Period of installation:

The total length of the installation time depends on number and qualification of the available local stuff.

A possible delay of the installation period will be additionally invoiced.

Remark: We will provide on-site service after 1 year. The customer will be asked to provide room, board, round-trip transportation, and a nominal 80USD daily subsidy per person.

contact: